Screw Parts

This description of screw parts is going to be a work in progress for

some time to come. Verbal descriptions of screw parts can only go

so far in conveying the parts. To try to more fully convey what

the parts are, examples have been drawn up to help with the

descriptions. The screw elements have been drawn in a very

general manner and are intended to convey the basics concepts of screw

geometry, not the geometry of any given extruder manufacturer.

The geometries are not quite correct, but are close enough to

convey the concepts to an audience wanting to learn about food

extrusion. The geometries used were for the purpose of ease of

drawing the parts.

The focus of this page is twin-screw extrusion. Single screw

extruders will have some parts and geometries not used or not possible

with

twin-screw extruders. This page will not show all of the parts

possible or available with twin-screw extrusion, but will focus on the

most common parts.

The basic use of measure on an extruder is the diameter of the screw

part. Using the diameter of the screw as the basic unit of

measure allows

extruder lengths and screw profiles to be described using a single set

of terms and measures from the smalllest extruder to the largest.

This can be best observed by looking at a screw element in

the axial direction (from the "front" or the "back" of the

screw). In many of the images below, there is a sphere 1D in

diameter to make visualization of the length of pieces in Diameters

more easy.

The length of screw parts are described in terms of diameters. In

general, the helical screw parts will be 0.5D, 1.0D, or 1.5D.

Other lengths are possible and available, depending on the

manufacturer.

The pitch of the screws are expressed in terms of the number of

diamters it takes for the flight to wrap 1 full revolution around the

screw (see images below). The most common pitches tend to be

0.25D, 0.5D, 0.75D, and 1.0D. The 0.25D pitch tends to be a

single-flight screw, this has not yet been drawn up for this site.

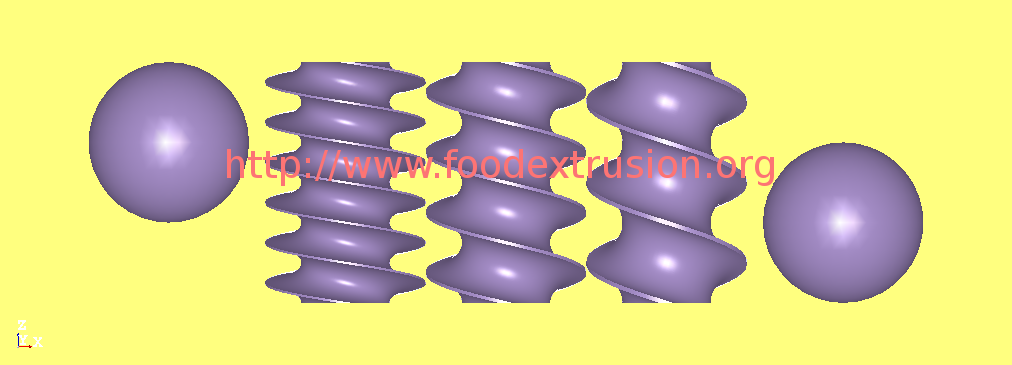

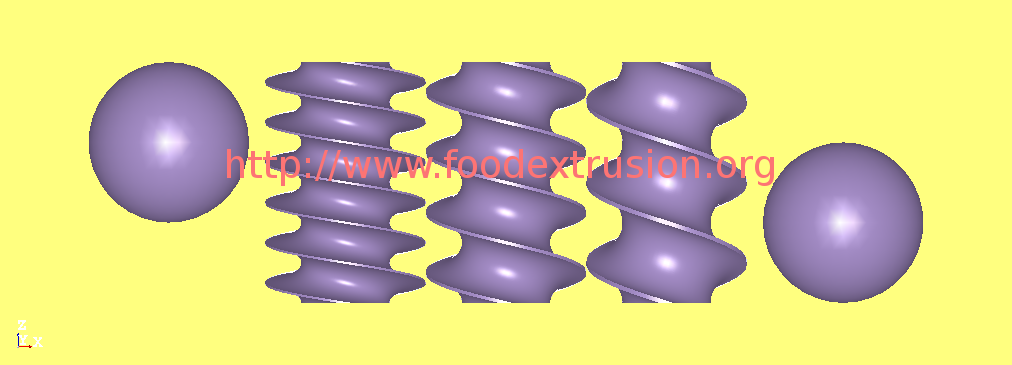

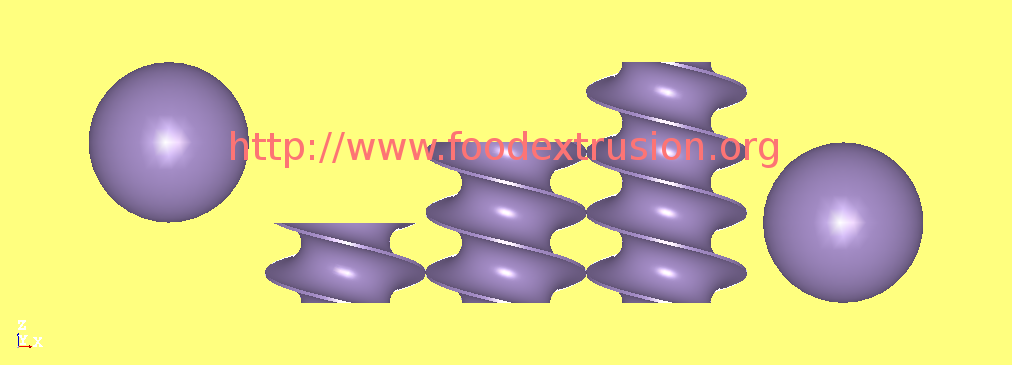

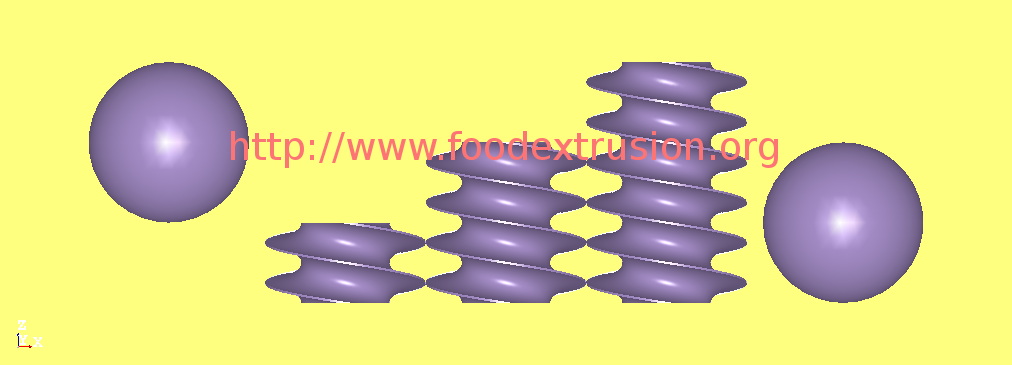

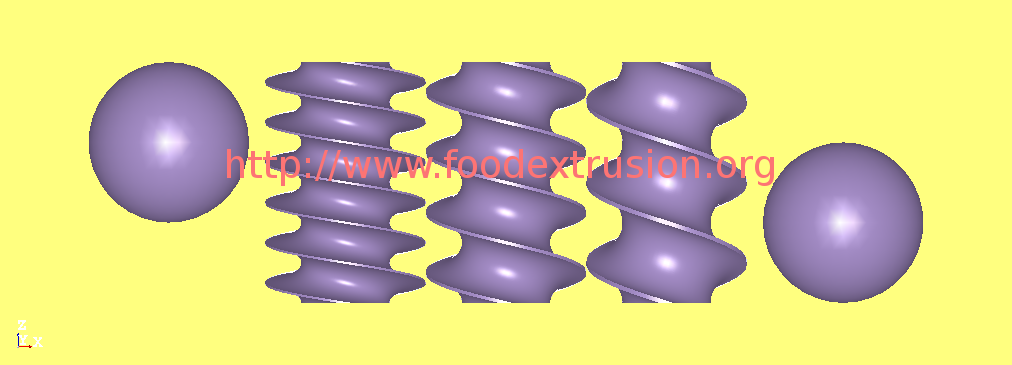

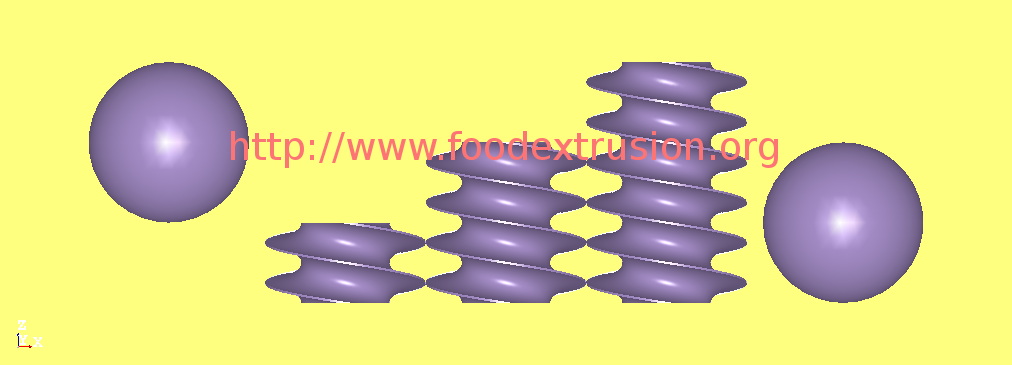

Below are images of the screw parts of different pitches. On the

left and right are the sphere 1D in diameter for comparison. The

spheres make it relatively easy to see these parts are 1.5D in

length. The screw element on the left has a pitch of 0.5, the

middle screw element has a pitch of 0.75, and the screw element on the

right has a pitch of 1.0. Using the screw element on the right

(1.0 pitch), you can follow the flight on the bottom of the image as it

rotates around the element (hiden behind the piece for part of the

revolution). When 1 full revolution around the element is

completed, the distance along the element is 1.0 D, so the point where

full rotation is completed is equal in height to the diameter of the

sphere (1.0 D). The 0.75 Pitch piece will complete a full

rotation of the flight in 0.75 D along the screw (or 2 rotations for

the 1.5 D length). The 0.5 Pitch will make 1 full rotation around

the screw in 0.5 D along the screw (or 3 rotations for the 1.5 D length.

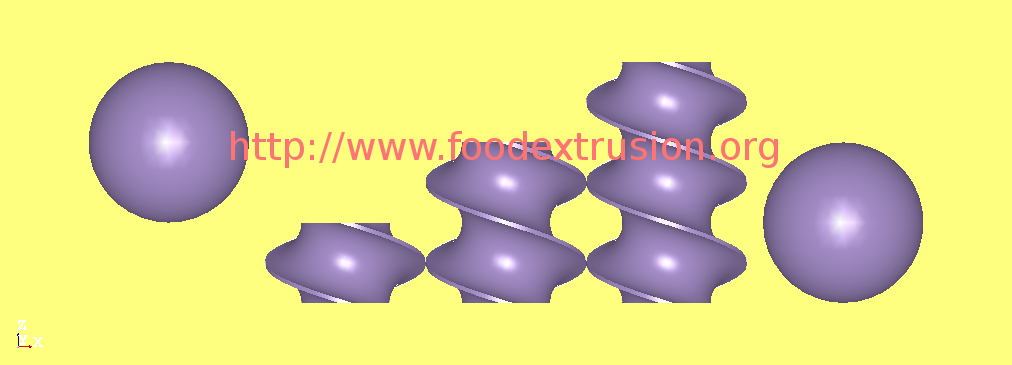

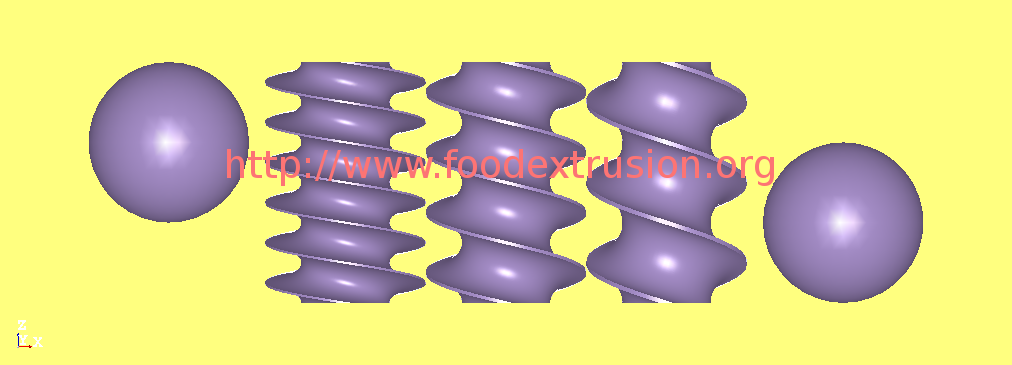

The length of these conveying pieces are typically 0.5 D, 1.0 D, and

1.5 D. The pieces for the three pitches are below (1.0 D pitch,

then 0.75 D pitch, then 0.5 D pitch).

Images for 1.0 D pitch (also call "full pitch")

Images for 3/4 pitch:

Images for 1/2 pitch:

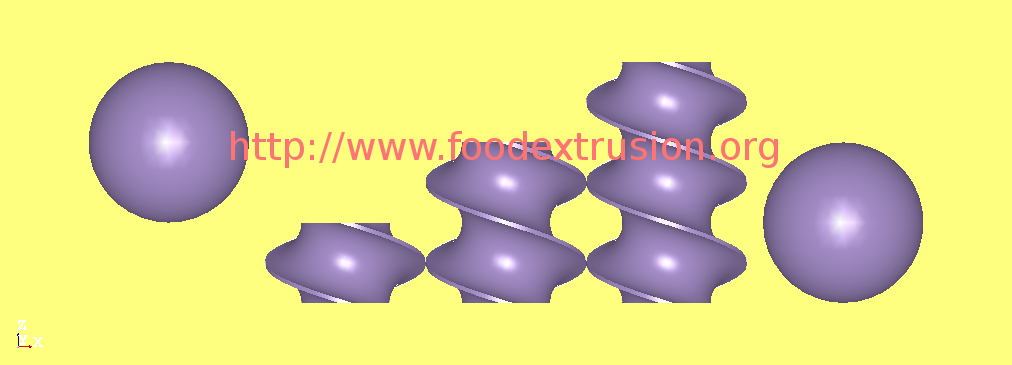

Conveying elements put work into the extudate slowly, paddles

(shearlocks) put work into the profile more rapidly. A paddle is

essentially an oval piece that is a poor conveying element, even when

configured as part of a group of elements set to "forward

conveying". Forward conveying is essentially lining the paddles

up so the general direction of the progression of the longest dimension

of the paddles (lobe) continue the direction of the conveying

elements. Neutral conveying is essentially setting the paddles so

from one paddle to the next in the profile, the lobes are offset by 90

degrees. Reverse conveying is essentially lining up the paddles

so the general direction of the progression of the lobes are opposite

the direction of the conveying elements. Generally, paddles will

be built up in sets equal to 0.5 D in length. For this web page,

the length of each paddle is 1/8 (0.125) D and blocks of 4 paddles were

created. Generally, for 0.5 D in length, a block of elements will

be offset by 90 degrees, so for the forward and reverse conveying

paddles, each paddle is offset by 30 degrees from the paddle

upstream.

The easiest way to demonstrate this is to show an animation of the

paddles as they would rotate in the extruder. For this animation,

the general direction of flow in the extuder is from left to

right. One way to look at the direction of conveying of the

paddles is to look at the top or bottom of the group of paddles.

If the "wave" that comes around goes from left to right, the parts are

forward conveying (direction of extrudate flow). If the "wave"

that comes around is right to left, the parts are reverse conveying

(opposite direction of extrudate flow). The middle set of paddles

are offset by 90 degrees, so will have no tendency to convey one

direction or the other.

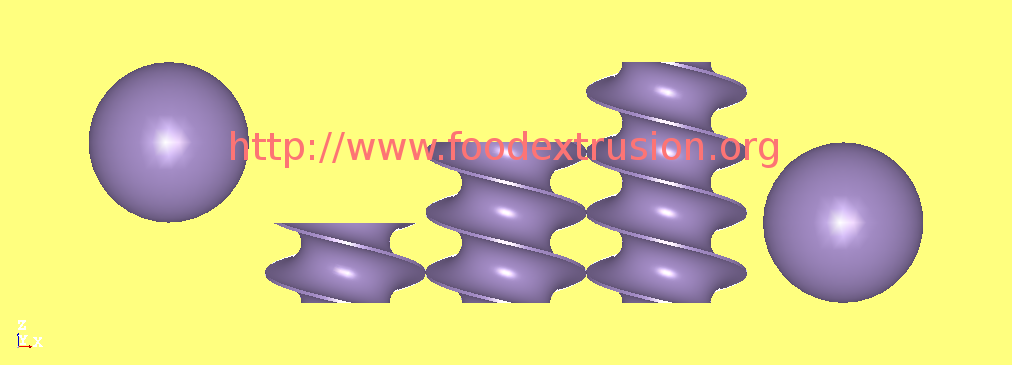

The screw elements are built up on the extruder shaft, resulting in the

screw profile being used. The animation below is an arbitrary

screw profile for an arbitrary extruder length - it is not meant to be

any particular profile for any particular extruder manufacturer or for

any particular product. The profile has a length for full pitch

(1.0 D) screws feeding into forward paddles. Coming out of the

forward paddles, there is another set of full pitch (1.0 D) screws

feeding into a set of three-quarters pitch (0.75 D) screw

elements. Coming off of those screws, there is a set of forward

paddles, followed by a set of reverse paddles. Coming off of

those paddles is a full pitch (1.0 D) screw element feeding a half

pitch (0.5 D) screws, which would then feed the die on the end of the

extruder. Not shown in the animation is the barrel surrounding

the screws.