Scale-up of geometrically similar extruders is

relatively straight-forward:

This sounds deceptively easy. It really can be this

easy. The largest caution in scaling up the die is a

significant change in geometry for the die between pilot plant

and production plant. More than one manufacturer uses a

pilot plant set-up that puts the die opening(s) directly in

front of the screw with no obstructions, but a much more

restrictive design on a commercial scale. When a page is

added on this subject, a link will be added here.

Below is a simple description of why geometrically similar

extruders scale-up in the manner described above. More

comprehensive and and rigorous descriptions are possible, but

will not be covered here.

If two extruders are geometrically similar, then we can do some

basic analysis of the system to demonstrate how the throughput of

the extruder scales up with diameter of the extruder and why

extruders should not be actively heated or cooled if there is a

desire to scale the process.

First we need to look at the geometry of the screw in a

scale-independent (dimensionless) manner. The screw element

has the following characteristics:

| Dimension |

Symbol indicating this variable |

Notes on the variable |

| Diameter of the screw |

D | This is the basis for 1 unit of length

measurement for the extruder. All other dimension will

be converted in terms of D. This measurement is also referred to as the outer diameter (Do). |

| Inner diameter of the screw |

Di | This is the narrowest dimension on the screw,

basically the diameter of the screw (D) minus double the

depth of the channel defined by the flights.

This is fixed on typical twin-screw extruders, but may

change along the length of the extruder for a single-screw

extruder or for twin-screw extruders where the 2 screws are

not parallel. |

| Flight thickness |

t |

This can be a constant thickness from the

root diameter to the outer diameter, but is more typically

variable and defined by the elliptical channel. |

| Length |

L |

This is the length of the extruder.

Extruder lengths are often expressed in terms of

diameters. |

| Pitch |

P |

This is the distance forward material in the

screw would travel per revolution of the screw in the area

of this pitch. A full pitch screw would move material

forward 1 D, 3/4 pitch would move material forward 0.75 D,

etc, assuming there are no inefficiencies in the conveying

of the screw. |

| Gap between the barrel wall and the diameter

of the screw part |

δ |

This is 1/2 the difference in diameter for

the barrel and the screw. |

| Fraction of the barrel cross-sectional area

occupied by the screw elemnt |

C1 | This is a mathematical constant across scales

for geometrically similar extruders |

| Ratio of the barrel diameter to screw

diameter |

C2 |

The barrel diameter is slightly larger than

the screw. Using a ratio of barrel diameter to screw

diameter will make the math more easily understood. |

| Created Variable |

C3 |

A constant that is a combination of a

function of C1 and C2. Use of C3

will make some later calculations be easier to work

with. |

Diagram of a screw element (side view):

Looking at the side view of a screw element, we can see that for

1 full revolution of a screw, the screw will convey the extrudate

forward equal to the pitch of the screw. This ignores any

inefficiencies in pumping ability in the screw. These

inefficiencies in pumping will also scale, and that will be

covered a bit later in this page. So: the volume of

extrudate conveyed forward is proportional to the diameter of the

extruder.

One revolution of a screw brings the extrudate forward by the

pitch of the screw (a full pitch screw for this example):

![]()

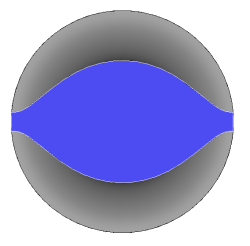

Diagram of a screw element (end view):

The blue in the image above indicates the cross-section of the

metal at the end of the screw. This is the area of the

cross-section in the barrel that is not extrudate. The

barrel is a slightly larger diameter than the screw, so if we show

a cross-section of the extruder with both the extrudate (red) and

the metal of the screw (blue), the full cross-section of the

barrel can be visualized:

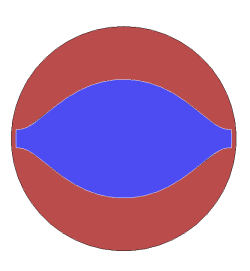

If the cross-section of the metal is removed, we are left with

just the cross-section of the extrudate:

The portion of the cross-sectional area of the barrel contains the screw element, not extrudate. This can be calculated:

The cross-sectional area of the barrel can be calculated:

The constant C3 was created to make the equation show a little

more clearly for later calculations.

So now we have the volume of extrudate carried forward per revolution of the screw by multiplying the cross-sectional area of the extrudate by the length the extruate is conveyed forward:

This tells us that the volume conveyed forward in an extruder screw is proportional to the diameter of the screw cubed. A similar calculation can be done to show the same relationship applies for twin-screw extruders. Since the residence time is proportional to diameter of the extruder for geometrically similar extruders, residence time is independent of extruder diameter for geometrically similar extruders being fed scaled feed rates and at equal screw speeds.

Heat generation in extruders occur

through viscous dissipation of energy being delivered through the

extruder screw(s). Energy input is a function of shear rate of the

extrudate. It can be shown that for geometrically similar

extruders fed at scaled feed rate, the energy input is a function

of shear rate and time in the extruder. The shear rates can be

calculated for any point in the extrudate. For the sake of an easy

geometry, a cross-section of the screw (in blue) and the extrudate

(in red) will be used for the example. This is shown in the

image below. The diameter of the barrel is D+2δ where δ is

the gap between the screw element and the barrel wall at the

narrowest point. For different areas in the extrudate, the

distance between the moving screw element and the barrrel

wall will be different.

For this example, we use the area of highest shear for the calculation, but the shear at any point could be used. The gap between the screw tip and the wall is the point of highest shear and can be expressed mathematically as: